Do you know how solar panels truly produce electricity? You’ve probably seen them on rooftops all over your neighborhood. We’ll examine solar cells, also known as photovoltaic (PV) solar cells, in this article. Solar cells are electrical devices that produce energy when exposed to photons, or tiny particles of light; this process is known as the photovoltaic effect. We will describe the operation of PV cells in this article. We’ll focus on silicon solar cells in particular because they make up the vast bulk of solar panels.

What Are Photovoltaic Cells?

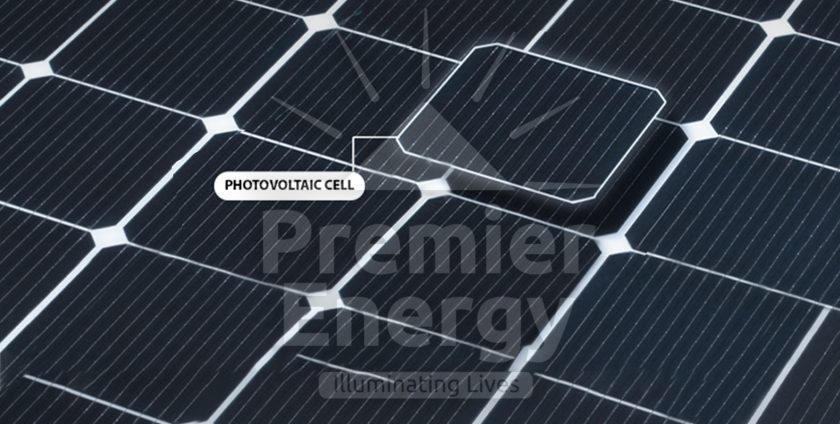

Six separate parts make up a solar module, but the photovoltaic cell, which actually produces power, is perhaps the most crucial one. The “photovoltaic effect,” which describes how a solar cell converts sunlight, which is composed of tiny particles called photons, into electrical energy, is the reason why we refer to solar cells as “photovoltaic,” or PV, for short.

Solar photovoltaic (PV) systems produce electricity by absorbing solar energy and turning it into an electrical current. A single solar module has several photovoltaic cells, and the total current produced by all of these cells when combined is sufficient to power your home.

How Do Photovoltaic Cells Work?

Four standard steps describe how a solar cell operates:

Light is absorbed, causing electrons to become unbound.

An electrical current is produced by free electrons flowing.

Wires receive the electrical current after it has been caught.

These three phases are the fundamental way that solar cells in Solar Panels transform energy from the sun into useful power. The photovoltaic effect is a complex process. Materials that can absorb photons from the sun and generate an electron flow make up a PV cell. A flow of electricity known as a direct current is produced when photons excite electrons. We’ll delve deeper into each of these phases below:

Absorption Of Light By Pv Cells

Sunlight touching a photovoltaic cell initiates the photovoltaic effect. The semiconductor material used to manufacture solar cells is typically silicon, which has undergone special processing to enable it to interact with the photons that make up the sunshine. The solar electricity you may use in your house is created when the incoming light energy knocks free electrons in silicon and starts them flowing together in a current.

Creation Of Current By The Flow Of Electrons

In order to create an electric field, each of the two layers of silicon used in photovoltaic technology has been carefully treated (referred to as “doping”) so that one side has a net positive charge and the other a net negative charge. An electrical current is created when an electric field acts as a diode, forcing freed electrons to flow through it in one direction.

Collection And Transmission Of Power

Metal plates on the sidewalls of each solar cell gather the free electrons after they have produced an electrical current and send them to wires. At this stage, power can travel as electrons via your home’s wiring to a solar inverter and back again.

A solar cell cannot generate enough useful electricity on its own to power anything larger than a small electronic device. Solar cells are strung together and mounted on top of a substrate like metal or glass to create solar panels, which are then installed in groups to form a solar power system. These solar panels can produce the quantity of electricity a residence may require. The output of a typical household solar panel with 60 cells could range from 220 to more than 400 watts.

Property owners will require variable numbers of solar panels to generate enough energy depending on parameters including temperature, sunlight hours, and power demand. Whatever the case, installing a photovoltaic system will probably need a large number of solar photovoltaic cells that work together to produce an electrical current.

How Are Solar Cells Made?

The essential components of solar panels sometimes referred to as photovoltaic cells, are what turn sunlight into electricity. Making solar cells entails numerous crucial procedures, including:

Production Of Silicon Ingot

Making a silicon ingot, which serves as the building block for solar cells, is the initial stage. High-purity silicon is melted in a crucible and gently drawn out to produce a solid cylindrical structure.

Wafer Slicing

The silicon ingot is then chopped using a wire saw or cutting instrument into tiny wafers. These wafers typically have a flat, smooth surface and a thickness of 200 micrometers.

Wafer Treatment

To enhance their electrical properties, the wafers go through a number of processes. Cleaning, surface texturing to increase light absorption, and doping with impurities to provide the necessary electrical properties are all included in this.

Formation Of Pn Junction

Making a PN junction on the wafer is the next stage. This is accomplished by diffusing a particular contaminant into the silicon surface, such as phosphorus or boron. As a result, separate zones of positive (P-type) and negative (N-type) conductivity are created, which are crucial for the solar cell’s operation.

Application Of Metal Contacts

The front and rear sides of the wafer are then coated with metal contacts to facilitate current flow. To maximize light absorption and reduce electrical resistance, the front surface of the device is often covered with a grid-like pattern of metal fingers.

Encapsulation Of Cells

To shield the finished solar cells from moisture, dust, and mechanical harm, they are enclosed in a transparent and protective material, like glass or a polymer.

Once the solar cells are created, they can be put together to create solar panels, which are made up of a number of interconnected cells. To produce electricity on a bigger scale, these panels can be added to solar arrays. In order to further improve the capabilities of solar cells, improvements in the manufacturing process are being made with a focus on increasing efficiency, lowering prices, and investigating alternative materials.

Efficiency Of Photovoltaic Cells

The type of semiconductor material and PV cell technology affect how effectively PV cells convert sunlight to energy. In the middle of the 1980s, the efficiency of commercially available PV panels was less than 10% on average. By 2015, it had improved to about 15%, and it is now reaching 25% for cutting-edge modules. Nearly 50% efficiency has been attained by experimental PV cells and PV cells for specialized applications, including as satellites in orbit.

Applications Of Photovoltaic Cells

Calculators and wristwatches are powered by the smallest photovoltaic systems. Larger systems can offer electricity to power communications equipment, a single home or company, or thousands of electrical users. They can also provide electricity to pump water.

Among The Benefits Of PV Systems Are:

- Power from PV systems can be sent to an electric power grid as well as places where there are no power lines for the purpose of distributing electricity.

- PV arrays can be any size and are easily erected.

- Building-mounted PV systems have a negligible environmental impact.

End Note

The discovery of the photovoltaic effect and its utilization to produce electricity are some of the biggest milestones in human history. Solar cells now play a vital role in our lives. With the current environmental crises, the shift towards solar energy is accelerating. This is all possible due to the photovoltaic effect and PV cells. In the future, solar cells will be a part of our regular lives in the form of solar backpacks, solar chargers, solar windows, solar roads, and even more. We cannot say what the future holds for PV cells but we can say one thing for sure that it is going to be bright for them.

Leave a Reply